Over 60% of logistics operators in Southeast Asia report storage inefficiencies due to outdated steel warehouse designs (JLL 2025 Logistics Report). GEYUE Steel (ASEAN Grade-1 Certified, License No. CB-2024-0015) analyzed 23 Cambodia projects and found:

– Space Wastage: Standard designs waste 22% vertical storage potential

– Energy Loss: Non-optimized steel framing increases cooling costs by 17%

Critical Gap: Most suppliers ignore AISC 360-16 compliance for tropical climates, risking corrosion failures within 5-8 years.

GEYUE’s 3-Step Custom Steel Warehouse Solutions

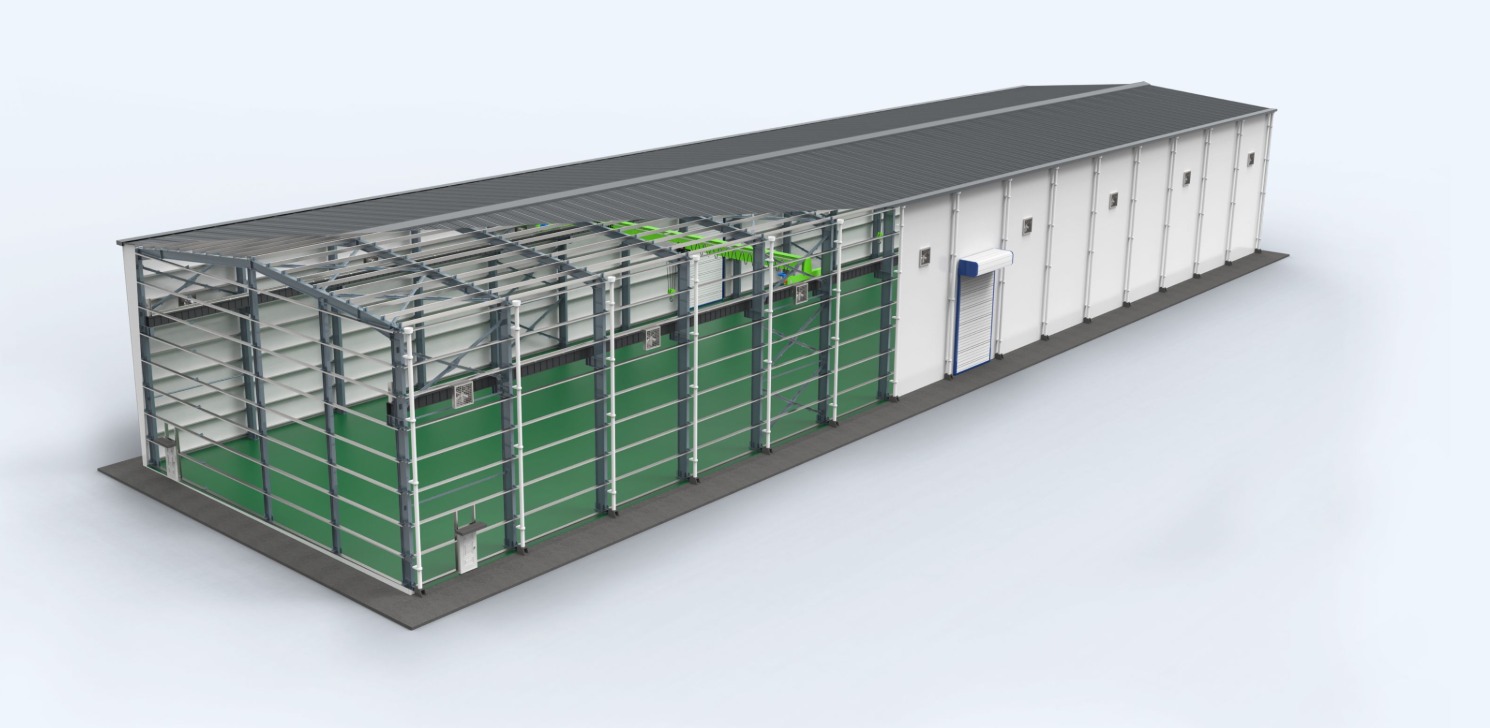

Step 1: AI-Driven Spatial Optimization

GEYUE’s SmartFrame 3.0 software (patent pending) uses machine learning to:

– Maximize column-free spans (up to 45m)

– Reduce steel weight by 15% via topology optimization

Case Study:

– Client: Phnom Penh E-Commerce Hub

– Result: 41% more pallet positions vs. standard designs

– Steel Usage: 52kg/㎡ (industry avg. 61kg/㎡)

Step 2: Climate-Adaptive Steel Solutions

GEYUE’s GX-785 Steel (SNI-certified) features:

– Corrosion Resistance: 2x lifespan in 85% humidity (tested per ASTM G85)

– Thermal Efficiency: Reflects 92% solar radiation, cutting cooling costs

| Parameter | GEYUE GX-785 | Conventional Steel |

| Lifespan (Tropical) | 40+ years | 18-22 years |

| Maintenance Cost/Year | $0.8/㎡ | $2.3/㎡ |

Step 3: Rapid Deployment with Modular Kits

GEYUE’s pre-engineered kits slash construction time:

– Foundation to Roof: 28 days for 10,000㎡ warehouses

– Cost Transparency: $89/㎡ all-inclusive (structure + cladding)

2025 Steel Warehouse Design Checklist (Free Download)

Avoid 4 critical mistakes:

1. Load Miscalculations: 55% of non-GEYUE projects exceed deflection limits (ASCE 7-22)

2. Poor Ventilation: GEYUE’s WindFlow Baffles boost airflow by 37%

3. Future-Proofing: Add 20% expansion capacity with bolt-on extensions

4. Fire Safety: GEYUE’s FireShield Coating achieves 2-hour fire rating (UL-certified)

益群网:终身分红,逆向推荐,不拉下线,也有钱赚!尖端资源,价值百万,一网打尽,瞬间拥有!多重收益,五五倍增,八级提成,后劲无穷!网址:1199.pw

digitalcommand.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

digitalcommand.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

optirank.shop – Content reads clearly, helpful examples made concepts easy to grasp.

rankcharge.shop – Loved the layout today; clean, simple, and genuinely user-friendly overall.

rankflow.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

seolaunch.shop – Appreciate the typography choices; comfortable spacing improved my reading experience.

rankhive.shop – Content reads clearly, helpful examples made concepts easy to grasp.

authoritygrowthengine.shop – Appreciate the typography choices; comfortable spacing improved my reading experience.

clickoptimizationhub.shop – Navigation felt smooth, found everything quickly without any confusing steps.

digitalmarketingzone.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

leadconversionstudio.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

proleadgeneration.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

digitalpresencelab.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

fullservicemarketing.shop – Loved the layout today; clean, simple, and genuinely user-friendly overall.

expertseostrategies.shop – Appreciate the typography choices; comfortable spacing improved my reading experience.

onlinebusinessbooster.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

prolevelmarketinghub.shop – Found practical insights today; sharing this article with colleagues later.

clickconversionpro.shop – Navigation felt smooth, found everything quickly without any confusing steps.

marketingsupportcenter.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

authorityranklabs.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

rankblaze.shop – Loved the layout today; clean, simple, and genuinely user-friendly overall.

smartgrowthengine.shop – Content reads clearly, helpful examples made concepts easy to grasp.

clickmarketingcenter.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

digitalperformancelab.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

powerfulgrowthagency.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

creativeclicksagency.shop – Found practical insights today; sharing this article with colleagues later.

superiorrankingstudio.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

smarttrafficboost.shop – Navigation felt smooth, found everything quickly without any confusing steps.

maximumtrafficservice.shop – Found practical insights today; sharing this article with colleagues later.

creativegrowthagency.shop – Appreciate the typography choices; comfortable spacing improved my reading experience.

seoagencysolutions.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

onlinerankingstudio.shop – Bookmarked this immediately, planning to revisit for updates and inspiration.

digitalconversionlab.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

ultimaterankbooster.shop – Appreciate the typography choices; comfortable spacing improved my reading experience.

backlinkhub.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

webauthorityboost.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

globalmarketingexperts.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

organicgrowthcenter.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

ultimaterankboost.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

seoenhancementpro.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

brandvisibilitypro.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

strategicseoagency.shop – Bookmarked this immediately, planning to revisit for updates and inspiration.

ultimatetrafficnetwork.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

premiumtrafficengine.shop – Navigation felt smooth, found everything quickly without any confusing steps.

onlinesuccesssystem.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

authorityrankingstudio.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

onlinegrowthengine.shop – Appreciate the typography choices; comfortable spacing improved my reading experience.

virallaunch.shop – Loved the layout today; clean, simple, and genuinely user-friendly overall.

focusedgrowthagency.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

nextgenmarketinghub.shop – Loved the layout today; clean, simple, and genuinely user-friendly overall.

brandsuccessstudio.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

growthpilot.shop – Loved the layout today; clean, simple, and genuinely user-friendly overall.

authoritybuildingcenter.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

professionalseostudio.shop – Found practical insights today; sharing this article with colleagues later.

nextlevelseohq.shop – Found practical insights today; sharing this article with colleagues later.

probacklinknetwork.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

seobacklinksolutions.shop – Found practical insights today; sharing this article with colleagues later.

serpstream.shop – Appreciate the typography choices; comfortable spacing improved my reading experience.

digitalsuccesspoint.shop – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

leadgenerationworks.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

premiumseoservice.shop – Content reads clearly, helpful examples made concepts easy to grasp.

digitalperformancecenter.shop – Color palette felt calming, nothing distracting, just focused, thoughtful design.

advancedmarketingsystems.shop – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

rankpro.shop – Content reads clearly, helpful examples made concepts easy to grasp.

elitemarketingsystems.shop – Found practical insights today; sharing this article with colleagues later.

powerrankoptimization.shop – Found practical insights today; sharing this article with colleagues later.

branddevelopmentworks.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

pixelmint.click – Content reads clearly, helpful examples made concepts easy to grasp.

novaclicks.click – Found practical insights today; sharing this article with colleagues later.

hyperrank.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

digitalbrandingworks.shop – Bookmarked this immediately, planning to revisit for updates and inspiration.

trafficgenerationpro.shop – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

peakclicks.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

rankgrid.click – Found practical insights today; sharing this article with colleagues later.

clickforgehub.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

turborank.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

rapidboost.click – Found practical insights today; sharing this article with colleagues later.

clickmatic.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

rankzilla.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

rankflare.click – Navigation felt smooth, found everything quickly without any confusing steps.

rankpilotpro.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

rankorbit.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

rankthread.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

rankmint.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

rankzone.click – Content reads clearly, helpful examples made concepts easy to grasp.

rankburst.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

clickorigin.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

clickphase.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

clickengineer.click – Navigation felt smooth, found everything quickly without any confusing steps.

viralcore.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

clickflux.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

rankverse.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

rankhero.click – Found practical insights today; sharing this article with colleagues later.

clickpeak.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

maximaclick.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

rankquest.click – Navigation felt smooth, found everything quickly without any confusing steps.

clickstreamer.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

rankboostx.click – Found practical insights today; sharing this article with colleagues later.

clickalley.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

clickanchor.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

propelclick.click – Navigation felt smooth, found everything quickly without any confusing steps.

clickattic.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

digitalshift.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

clicklance.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

rankjet.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

nextclicks.click – Content reads clearly, helpful examples made concepts easy to grasp.

ranklogic.click – Found practical insights today; sharing this article with colleagues later.

clicklyst.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

ranknova.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

growthlane.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

clickspider.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

rankstack.click – Navigation felt smooth, found everything quickly without any confusing steps.

rankloom.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

rankmaximo.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

swiftboost.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

clickrealm.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

ultraclicks.click – Found practical insights today; sharing this article with colleagues later.

clickamplify.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

clickcrafted.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

webreach.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

clicklegend.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

marketingsignal.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

digitalreach.click – Navigation felt smooth, found everything quickly without any confusing steps.

digitalascend.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

webinfluence.click – Found practical insights today; sharing this article with colleagues later.

leadtrajectory.click – Found practical insights today; sharing this article with colleagues later.

growthaccelerator.click – Content reads clearly, helpful examples made concepts easy to grasp.

searchcommand.click – Found practical insights today; sharing this article with colleagues later.

marketingorbit.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

rankvelocity.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

digitalgrowthhq.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

marketingdrive.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

growthsystems.click – Found practical insights today; sharing this article with colleagues later.

rankvelocity.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

trafficlogic.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

webtrafficpro.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

trafficpath.click – Navigation felt smooth, found everything quickly without any confusing steps.

rankvelocity.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

Your blog is a treasure trove of helpful content—please keep it coming!

You’ve truly created such a welcoming and insightful space here. Kudos to you!

I’m quite into reading blogs lately, and yours is one of the best I’ve come across. I’m adding it to my favorites to stay updated.

leadmechanics.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

clickboostlab.click – Content reads clearly, helpful examples made concepts easy to grasp.

rankexpansion.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

rankcontrol.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

searchlift.click – Content reads clearly, helpful examples made concepts easy to grasp.

You raised some excellent points. After doing some research on the topic, I found that most people align with the insights shared on your blog.

Your approach to creating content is truly remarkable. This article has been incredibly insightful and has provided me with an excellent solution to my challenges.

Your approach to creating content is truly exceptional. This article was highly informative and provided me with an excellent solution to my challenges.

owntheserp.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

hacktheclick.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

netuplift.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

clickdomination.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

zeroposition.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

какой стайлер дайсон лучше купить [url=https://fen-dn-kupit-12.ru/]fen-dn-kupit-12.ru[/url] .

купить фен дайсон официальный сайт [url=https://fen-dn-kupit-13.ru/]купить фен дайсон официальный сайт[/url] .

купить дайсон стайлер с насадками официальный сайт для волос цен… [url=https://stajler-dsn-1.ru/]stajler-dsn-1.ru[/url] .

стайлер дайсон цена для волос с насадками официальный сайт купит… [url=https://fen-dn-kupit-13.ru/]стайлер дайсон цена для волос с насадками официальный сайт купит…[/url] .

стайлер дайсон для волос с насадками цена официальный сайт купит… [url=https://fen-dn-kupit-12.ru/]fen-dn-kupit-12.ru[/url] .

официальный сайт дайсон стайлер для волос купить цена с насадкам… [url=https://stajler-dsn-1.ru/]официальный сайт дайсон стайлер для волос купить цена с насадкам…[/url] .

стайлер для волос дайсон с насадками официальный сайт купить цен… [url=https://fen-dn-kupit-13.ru/]стайлер для волос дайсон с насадками официальный сайт купить цен…[/url] .

дайсон стайлер для волос официальный сайт цена купить с насадкам… [url=https://fen-dn-kupit-12.ru/]fen-dn-kupit-12.ru[/url] .

купить дайсон стайлер для волос с насадками официальный сайт цен… [url=https://stajler-dsn-1.ru/]stajler-dsn-1.ru[/url] .

купить дайсон стайлер с насадками для волос цена официальный сай… [url=https://fen-dn-kupit-13.ru/]купить дайсон стайлер с насадками для волос цена официальный сай…[/url] .

фен купить dyson [url=https://fen-dn-kupit-12.ru/]фен купить dyson[/url] .

фен купить дайсон оригинал [url=https://stajler-dsn-1.ru/]stajler-dsn-1.ru[/url] .

купить пылесос дайсон в санкт [url=https://dn-pylesos.ru/]dn-pylesos.ru[/url] .

купить пылесос дайсон абсолют [url=https://dn-pylesos.ru/]купить пылесос дайсон абсолют[/url] .

пылесосы dyson официальный [url=https://dn-pylesos.ru/]пылесосы dyson официальный[/url] .

купить пылесос дайсон в нижнем [url=https://dn-pylesos.ru/]купить пылесос дайсон в нижнем[/url] .

webignite.click – Content reads clearly, helpful examples made concepts easy to grasp.

digitalclimb.click – Navigation felt smooth, found everything quickly without any confusing steps.

backlinkhub.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

купить кейс для выпрямителя дайсон [url=https://vypryamitel-dn-4.ru/]купить кейс для выпрямителя дайсон[/url] .

выпрямитель для волос dyson airstrait ht01 [url=https://vypryamitel-dn-4.ru/]выпрямитель для волос dyson airstrait ht01[/url] .

serpcontrol.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

dyson выпрямитель для волос [url=https://vypryamitel-dn-4.ru/]dyson выпрямитель для волос[/url] .

rankmomentum.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

scaleonline.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

clicktoconvert.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

searchimpact.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

trafficsurge.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

фен выпрямитель дайсон купить в сургуте [url=https://vypryamitel-dn-4.ru/]vypryamitel-dn-4.ru[/url] .

rankengine.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

webauthority.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

digitaltraffic.click – Navigation felt smooth, found everything quickly without any confusing steps.

onlineleads.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

smartvisibility.click – Found practical insights today; sharing this article with colleagues later.

выпрямитель дайсон hs07 купить [url=https://vypryamitel-dn-kupit-4.ru/]vypryamitel-dn-kupit-4.ru[/url] .

выпрямитель для волос dyson airstrait купить [url=https://vypryamitel-dn-kupit-4.ru/]выпрямитель для волос dyson airstrait купить[/url] .

купить фен выпрямитель дайсон [url=https://vypryamitel-dn-kupit-4.ru/]купить фен выпрямитель дайсон[/url] .

выпрямитель дайсон hs07 купить [url=https://vypryamitel-dn-kupit-4.ru/]vypryamitel-dn-kupit-4.ru[/url] .

pixelpilot.click – Content reads clearly, helpful examples made concepts easy to grasp.

searchspark.click – Content reads clearly, helpful examples made concepts easy to grasp.

фен выпрямитель дайсон airstrait купить [url=https://vypryamitel-dsn-kupit-4.ru/]фен выпрямитель дайсон airstrait купить[/url] .

funnelfusion.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

traffictide.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

дайсон стайлер купить выпрямитель [url=https://vypryamitel-dsn-kupit-4.ru/]дайсон стайлер купить выпрямитель[/url] .

реклама наркологической клиники [url=https://seo-kejsy7.ru/]реклама наркологической клиники[/url] .

онлайн школа 10-11 класс [url=https://shkola-onlajn13.ru/]shkola-onlajn13.ru[/url] .

какой выпрямитель дайсон купить [url=https://vypryamitel-dsn-kupit-4.ru/]какой выпрямитель дайсон купить[/url] .

успешные кейсы seo [url=https://seo-kejsy7.ru/]успешные кейсы seo[/url] .

boostbureau.click – Navigation felt smooth, found everything quickly without any confusing steps.

онлайн школа 10-11 класс [url=https://shkola-onlajn13.ru/]shkola-onlajn13.ru[/url] .

conversioncrew.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

serpshift.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

rankboost.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

seowins.click – Content reads clearly, helpful examples made concepts easy to grasp.

dyson выпрямитель купить оригинал [url=https://vypryamitel-dsn-kupit-4.ru/]vypryamitel-dsn-kupit-4.ru[/url] .

современные seo кейсы [url=https://seo-kejsy7.ru/]seo-kejsy7.ru[/url] .

дистанционное обучение 10-11 класс [url=https://shkola-onlajn13.ru/]shkola-onlajn13.ru[/url] .

auditpro.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

linklift.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

keywordking.click – Found practical insights today; sharing this article with colleagues later.

многоуровневый линкбилдинг [url=https://seo-kejsy7.ru/]seo-kejsy7.ru[/url] .

backlinkboss.click – Found practical insights today; sharing this article with colleagues later.

дистанционное обучение 7 класс [url=https://shkola-onlajn13.ru/]дистанционное обучение 7 класс[/url] .

onpagefix.click – Found practical insights today; sharing this article with colleagues later.

sitesprint.click – Content reads clearly, helpful examples made concepts easy to grasp.

funnelfix.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

ctrboost.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

landinglift.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

retargetpro.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

roigrowth.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

offeroptim.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

marketbetter.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

clicktoclient.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

scalenow.click – Content reads clearly, helpful examples made concepts easy to grasp.

drivetraffic.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

growonline.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

boostmysite.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

melbet website [url=https://rusfusion.ru/]melbet website[/url] .

курсовые заказ [url=https://kupit-kursovuyu-43.ru/]курсовые заказ[/url] .

growmybrand.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

improveseo.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

performanceads.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

rankmysite.click – Content reads clearly, helpful examples made concepts easy to grasp.

growthmarketing.click – Content reads clearly, helpful examples made concepts easy to grasp.

выполнение учебных работ [url=https://kupit-kursovuyu-43.ru/]kupit-kursovuyu-43.ru[/url] .

официальный сайт бк мелбет [url=http://rusfusion.ru/]официальный сайт бк мелбет[/url] .

seoservices.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

rankhigher.click – Found practical insights today; sharing this article with colleagues later.

стоимость написания курсовой работы на заказ [url=https://kupit-kursovuyu-43.ru/]kupit-kursovuyu-43.ru[/url] .

ppcmanagement.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

betting sports online [url=https://rusfusion.ru/]betting sports online[/url] .

funnelbuilder.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

googleadspro.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

студенческие работы на заказ [url=https://kupit-kursovuyu-43.ru/]студенческие работы на заказ[/url] .

melbet бк [url=http://www.rusfusion.ru]melbet бк[/url] .

marketingautomation.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

socialadspro.click – Navigation felt smooth, found everything quickly without any confusing steps.

socialmarketing.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

crmsetup.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

analyticsreport.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

funnelpilot.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

webdesignstudio.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

roiengine.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

signaltrack.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

funnelforge.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

1win canlı kazino [url=https://1win5762.help]1win canlı kazino[/url]

1win canlı kazino [url=www.1win5762.help]www.1win5762.help[/url]

serpstudio.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

keywordcraft.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

authoritylab.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

rankharbor.click – Navigation felt smooth, found everything quickly without any confusing steps.

оптимизация сайта франция [url=https://prodvizhenie-sajtov-v-moskve115.ru/]prodvizhenie-sajtov-v-moskve115.ru[/url] .

глубокий комлексный аудит сайта [url=https://prodvizhenie-sajtov-v-moskve119.ru/]глубокий комлексный аудит сайта[/url] .

auditpilot.click – Navigation felt smooth, found everything quickly without any confusing steps.

1win cashback bonus [url=https://www.1win5762.help]1win cashback bonus[/url]

продвижение в google [url=https://prodvizhenie-sajtov-v-moskve115.ru/]prodvizhenie-sajtov-v-moskve115.ru[/url] .

компании занимающиеся продвижением сайтов [url=https://prodvizhenie-sajtov-v-moskve119.ru/]компании занимающиеся продвижением сайтов[/url] .

onpagelab.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

adnivo.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

klickivo.click – Found practical insights today; sharing this article with colleagues later.

rankvanta.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

продвижение сайтов в москве [url=https://prodvizhenie-sajtov-v-moskve115.ru/]продвижение сайтов в москве[/url] .

интернет продвижение москва [url=https://prodvizhenie-sajtov-v-moskve119.ru/]интернет продвижение москва[/url] .

growvanta.click – Navigation felt smooth, found everything quickly without any confusing steps.

1win haqqında rəylər [url=http://1win5762.help]http://1win5762.help[/url]

internet seo [url=https://prodvizhenie-sajtov-v-moskve115.ru/]prodvizhenie-sajtov-v-moskve115.ru[/url] .

продвижение сайтов в москве [url=https://prodvizhenie-sajtov-v-moskve119.ru/]продвижение сайтов в москве[/url] .

leadvero.click – Found practical insights today; sharing this article with colleagues later.

funnelio.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

convertlyo.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

metricovo.click – Content reads clearly, helpful examples made concepts easy to grasp.

localsprint.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

localbooster.click – Navigation felt smooth, found everything quickly without any confusing steps.

locallift.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

bizfunnel.click – Content reads clearly, helpful examples made concepts easy to grasp.

leadboostlab.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

clickgrowthhub.click – Found practical insights today; sharing this article with colleagues later.

rankbooststudio.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

semmarketing.click – Found practical insights today; sharing this article with colleagues later.

funnelscalelab.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

оптимизация сайта франция [url=https://poiskovoe-seo-v-moskve.ru/]poiskovoe-seo-v-moskve.ru[/url] .

маркетинговые стратегии статьи [url=https://statyi-o-marketinge2.ru/]statyi-o-marketinge2.ru[/url] .

login to 1win [url=https://1win5745.help]login to 1win[/url]

аудит продвижения сайта [url=https://poiskovoe-seo-v-moskve.ru/]аудит продвижения сайта[/url] .

оптимизация сайта блог [url=https://statyi-o-marketinge2.ru/]statyi-o-marketinge2.ru[/url] .

netassist.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

webrelay.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

connecthub.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

onlineboost.click – Content reads clearly, helpful examples made concepts easy to grasp.

профессиональное продвижение сайтов [url=https://poiskovoe-seo-v-moskve.ru/]профессиональное продвижение сайтов[/url] .

статьи про продвижение сайтов [url=https://statyi-o-marketinge2.ru/]статьи про продвижение сайтов[/url] .

1win token listing date [url=http://1win5745.help/]http://1win5745.help/[/url]

раскрутка сайта франция [url=https://poiskovoe-seo-v-moskve.ru/]poiskovoe-seo-v-moskve.ru[/url] .

сео блог [url=https://statyi-o-marketinge2.ru/]сео блог[/url] .

1win listing date [url=http://1win5745.help]http://1win5745.help[/url]

speedserve.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

clicknetwork.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

websprint.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

browsebuddy.click – Content reads clearly, helpful examples made concepts easy to grasp.

1win bet deposit [url=http://1win5745.help/]http://1win5745.help/[/url]

routerready.click – Appreciate the typography choices; comfortable spacing improved my reading experience.

вход в мостбет [url=www.mostbet2026.help]вход в мостбет[/url]

streamserve.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

connectcraft.click – Content reads clearly, helpful examples made concepts easy to grasp.

netguide.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

onlineport.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

servespark.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

курсы seo [url=https://kursy-seo-5.ru/]курсы seo[/url] .

курсы по seo [url=https://kursy-seo-4.ru/]курсы по seo[/url] .

mostbet baixar [url=mostbet2026.help]mostbet2026.help[/url]

учиться seo [url=https://kursy-seo-4.ru/]kursy-seo-4.ru[/url] .

курсы seo [url=https://kursy-seo-5.ru/]курсы seo[/url] .

webnexus.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

sitesupport.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

signalshift.click – Navigation felt smooth, found everything quickly without any confusing steps.

webfixer.click – Found practical insights today; sharing this article with colleagues later.

netmosaic.click – Content reads clearly, helpful examples made concepts easy to grasp.

скачать мостбет казино [url=http://mostbet2026.help]http://mostbet2026.help[/url]

продвижение обучение [url=https://kursy-seo-4.ru/]kursy-seo-4.ru[/url] .

продвижение обучение [url=https://kursy-seo-5.ru/]kursy-seo-5.ru[/url] .

мостбет.сом [url=www.mostbet2026.help]мостбет.сом[/url]

seo онлайн [url=https://kursy-seo-4.ru/]seo онлайн[/url] .

курс seo [url=https://kursy-seo-5.ru/]kursy-seo-5.ru[/url] .

trafficdock.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

pixelroute.click – Color palette felt calming, nothing distracting, just focused, thoughtful design.

rankpulse.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

boostsignal.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

netamplify.click – Content reads clearly, helpful examples made concepts easy to grasp.

leadcircuit.click – Content reads clearly, helpful examples made concepts easy to grasp.

sitebloom.click – Loved the layout today; clean, simple, and genuinely user-friendly overall.

двухкомнатная квартира жк светский лес сочи

химчистка белой обуви отдать обувь в химчистку

searchrocket.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

adsforge.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

seobeacon.click – Pages loaded fast, images appeared sharp, and formatting stayed consistent.

digitaltide.click – Found practical insights today; sharing this article with colleagues later.

campaigncraft.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

улучшение баннеров реклама [url=https://reklamnyj-kreativ4.ru/]reklamnyj-kreativ4.ru[/url] .

upster pro [url=https://reklamnyj-kreativ5.ru/]upster pro[/url] .

улучшение hero карточки [url=https://reklamnyj-kreativ4.ru/]улучшение hero карточки[/url] .

карточки товаров wildberries [url=https://reklamnyj-kreativ5.ru/]карточки товаров wildberries[/url] .

лазерный проектор интернет-магазин проекторов

upster pro [url=https://reklamnyj-kreativ4.ru/]upster pro[/url] .

анализ наружной рекламы [url=https://reklamnyj-kreativ5.ru/]анализ наружной рекламы[/url] .

Играешь в казино? https://t.me/ простой вход, удобная регистрация и доступ ко всем возможностям платформы. Стабильная работа, адаптация под разные устройства и комфортный пользовательский опыт.

Любишь азарт? upx играть онлайн в популярные игры и режимы. Быстрый вход, удобная регистрация, стабильная работа платформы, понятный интерфейс и комфортные условия для игры в любое время на компьютере и мобильных устройствах.

crash 1вин [url=https://1win12050.ru]https://1win12050.ru[/url]

запоминаемость рекламы [url=https://reklamnyj-kreativ5.ru/]reklamnyj-kreativ5.ru[/url] .

Любишь азарт? upx играть онлайн легко и удобно. Быстрый доступ к аккаунту, понятная навигация, корректная работа на любых устройствах и комфортный формат для пользователей.

Play online puzzles https://kwork.com/user/ivanjar anytime and train your logic and attention skills. Classic and themed puzzles, various sizes, simple gameplay, and comfortable play on computers and mobile devices.

мостбет вход, регистрация [url=http://mostbet2027.help]http://mostbet2027.help[/url]

1win apk [url=https://1win12050.ru]1win apk[/url]

motsbet [url=http://mostbet2027.help]motsbet[/url]

mostbet mobile [url=mostbet2027.help]mostbet2027.help[/url]

1win лимит депозита [url=www.1win12050.ru]www.1win12050.ru[/url]

1win депозит без комиссии [url=1win12050.ru]1win12050.ru[/url]

Hello, yeah this piece of writing is actually nice and I have learned lot of things from it about blogging. thanks.

регистрация рио бет казино

сколько стоит люстра люстра потолочная деревянная купить

мужские костюмы недорого купить мужские костюмы

vavada verifikacija računa [url=https://vavada2007.help/]https://vavada2007.help/[/url]

Электромонтажные работы https://electric-top.ru в Москве и области. Круглосуточный выезд электриков. Гарантия на работу. Аварийный электрик.

I’m gone to say to my little brother, that he should also visit this webpage on regular basis to obtain updated from most recent information.

https://www.fst.tw/2026/01/27/le-catalogue-iron-tv-pro-la-diversite-au-service-du-divertissement/

коррозия у авто? антикорозийка для авто эффективная защита от влаги, соли и реагентов. Комплексная обработка кузова и днища, качественные составы и надёжный результат для новых и подержанных авто.

vavada metode isplate hrvatska [url=https://www.vavada2007.help]https://www.vavada2007.help[/url]

digitaltide.click – Mobile version looks perfect; no glitches, fast scrolling, crisp text.

дайсон спб официальный магазин [url=https://pylesos-dn-6.ru/]pylesos-dn-6.ru[/url] .

дайсон официальный сайт в санкт петербург [url=https://dn-pylesos-3.ru/]dn-pylesos-3.ru[/url] .

дайсон фен купить оригинальный спб [url=https://pylesos-dn-7.ru/]pylesos-dn-7.ru[/url] .

Коррозия на авто? https://antikor-service.ru мы используем передовые шведские материалы Mercasol и Noxudol для качественной защиты днища и скрытых полостей кузова. На все работы предоставляется гарантия сроком 8 лет, а цены остаются доступными благодаря прямым поставкам материалов от производителя.

vavada službena stranica Hrvatska [url=www.vavada2007.help]vavada službena stranica Hrvatska[/url]

дайсон фен купить оригинальный спб [url=https://pylesos-dn-6.ru/]pylesos-dn-6.ru[/url] .

дайсон фен купить оригинальный спб [url=https://pylesos-dn-7.ru/]pylesos-dn-7.ru[/url] .

vavada aviator mobilno [url=www.vavada2007.help]vavada aviator mobilno[/url]

Планируете мероприятие? AI event уникальные интерактивные форматы с нейросетями для бизнеса. Мы разрабатываем корпоративные мероприятия под ключ — будь то тимбилдинги, обучающие мастер?классы или иные активности с ИИ, — с учётом ваших целей. Работаем в Москве, Санкт?Петербурге и регионах. AI?Event специализируется на организации корпоративных мероприятий с применением технологий искусственного интеллекта.

Украшения для пирсинга https://piercing-opt.ru купить оптом украшения для пирсинга. Напрямую от производителя, выгодные цены, доставка. Отличное качество.

пылесос dyson [url=https://pylesos-dn-7.ru/]пылесос dyson[/url] .

сайт дайсон спб [url=https://pylesos-dn-6.ru/]pylesos-dn-6.ru[/url] .

sitepilot.click – Content reads clearly, helpful examples made concepts easy to grasp.

netvortex.click – Bookmarked this immediately, planning to revisit for updates and inspiration.

pin-up Huawei yüklə [url=pinup2009.help]pinup2009.help[/url]

reachriver.click – Overall, professional vibe here; trustworthy, polished, and pleasantly minimal throughout.

Ищешь сокращатель сылок? https://l1l.kz надежный сокращатель ссылок в Казахстане, рекомендуем заглянуть на сайт, где весь функционал доступен бесплатно и без регистрации

пылесосы дайсон [url=https://pylesos-dn-7.ru/]пылесосы дайсон[/url] .

дайсон пылесос спб [url=https://pylesos-dn-6.ru/]pylesos-dn-6.ru[/url] .

leadnest.click – Found practical insights today; sharing this article with colleagues later.

Противопожарные двери https://bastion52.ru купить для защиты помещений от огня и дыма. Большой выбор моделей, классы огнестойкости EI30, EI60, EI90, качественная фурнитура и соответствие действующим стандартам.

Нужны цветы? купить букет цветов закажите цветы с доставкой на дом или в офис. Большой выбор букетов, свежие цветы, стильное оформление и точная доставка. Подойдёт для праздников, сюрпризов и важных событий.

O’zbekiston uchun https://uzresearch.uz iqtisodiyot, moliya, ijtimoiy jarayonlar, bozorlar va mintaqaviy rivojlanish kabi asosiy sohalarda tadqiqotlar olib boradigan analitik platforma. Strukturaviy ma’lumotlar va professional tahlil.

Savdo va biznes https://infinitytrade.uz uchun xalqaro platforma. Bozor tahlili, xalqaro savdo, eksport va import, logistika, moliya va biznes yangiliklari. Tadbirkorlar va kompaniyalar uchun foydali materiallar, sharhlar va ma’lumotlar.

Ijtimoiy rivojlanish https://ijtimoiy.uz va jamoat hayoti uchun portal. Yangiliklar, tahlillar, tashabbuslar, loyihalar va ekspert fikrlari. Ijtimoiy jarayonlar, fuqarolik ishtiroki, ta’lim va jamiyatni rivojlantirish bo’yicha materiallar.

Foydali maslahatlar https://grillades.uz va g’oyalar bilan panjara va barbekyu haqida loyiha. Retseptlar, panjara qilish texnikasi va jihozlar va aksessuarlarni tanlash. Mukammal ta’m va muvaffaqiyatli ochiq havoda uchrashuvlar uchun hamma narsa.

Qurilish materiallari https://emtb.uz turar-joy va sanoat qurilishi uchun beton va temir-beton. Poydevorlar, pollar va inshootlar uchun ishonchli yechimlar, standartlarga muvofiqlik, izchil sifat va loyihaga xos yetkazib berish.

дайсон сервисный центр санкт петербург [url=https://pylesos-dn-7.ru/]pylesos-dn-7.ru[/url] .

купить пылесос дайсон в санкт [url=https://pylesos-dn-6.ru/]pylesos-dn-6.ru[/url] .

Ijtimoiy jarayonlar https://qqatx.uz va jamiyat taraqqiyoti bo’yicha onlayn axborot platformasi. Tegishli materiallar, tahliliy sharhlar, tadqiqotlar va murakkab mavzularning tushuntirishlari aniq va tuzilgan formatda.

Любишь азарт? комета казино официальное зеркало современные слоты, live-форматы, понятные правила и удобный доступ с ПК и смартфонов. Играйте онлайн в удобное время.

Играешь в казино? ап икс казино Слоты, рулетка, покер и live-дилеры, простой интерфейс, стабильная работа сайта и возможность играть онлайн без сложных настроек.

pin-up az aviator [url=https://pinup2009.help/]https://pinup2009.help/[/url]

Играешь в казино? ап х Слоты, рулетка, покер и live-дилеры, простой интерфейс, стабильная работа сайта и возможность играть онлайн без сложных настроек.

Avia Masters de BGaming es un juego crash con RTP del 97% donde apuestas desde 0,10€ hasta 1.000€, controlas la velocidad de vuelo de un avion que recoge multiplicadores (hasta x250) mientras evita cohetes que reducen ganancias a la mitad, con el objetivo de aterrizar exitosamente en un portaaviones para cobrar el premio acumulado

play avia masters

pin-up app yüklə [url=http://pinup2009.help/]http://pinup2009.help/[/url]

Avia Masters de BGaming es un juego crash con RTP del 97% donde apuestas desde 0,10€ hasta 1.000€, controlas la velocidad de vuelo de un avion que recoge multiplicadores (hasta x250) mientras evita cohetes que reducen ganancias a la mitad, con el objetivo de aterrizar exitosamente en un portaaviones para cobrar el premio acumulado

https://share.google/fJQDVleCdhoK2m6BE

Avia Masters de BGaming es un juego crash con RTP del 97% donde apuestas desde 0,10€ hasta 1.000€, controlas la velocidad de vuelo de un avion que recoge multiplicadores (hasta x250) mientras evita cohetes que reducen ganancias a la mitad, con el objetivo de aterrizar exitosamente en un portaaviones para cobrar el premio acumulado

https://share.google/7XTgktqOFuvrM3mdQ

Криминальная хроника В зоне СВО отмечается активизация беспилотной авиации. Военные эксперты анализируют тактику и эффективность использования дронов в современных боевых действиях. Ведутся разработки по защите от беспилотных летательных аппаратов.

pin-up çıxarış səhifəsi [url=www.pinup2009.help]www.pinup2009.help[/url]

Company commercial video production services in italy

dyson купить спб [url=https://pylesos-dn-7.ru/]dyson купить спб[/url] .

dyson v15 спб [url=https://pylesos-dn-6.ru/]pylesos-dn-6.ru[/url] .

Spiele Spiele Fancy Fruits Slot Review in Online-Casinos bieten eine Vielzahl an Unterhaltung und Gewinnchancen, die Spieler aus der ganzen Welt anziehen. Mit aufregenden Grafiken und innovativen Funktionen sind die Spiele leicht zuganglich und sorgen fur ein unvergessliches Erlebnis im virtuellen Spielumfeld.

ко ланта ко ланте

This is very interesting, You’re a very skilled blogger. I’ve joined your rss feed and look forward to seeking more of your wonderful post. Also, I’ve shared your site in my social networks!

zumospin.com

Русские подарки и сувениры купить в широком ассортименте. Классические и современные изделия, национальные символы, качественные материалы и оригинальные идеи для памятных и душевных подарков.

What’s up everyone, it’s my first pay a quick visit at this web site, and post is genuinely fruitful for me, keep up posting these articles.

byueuropaviagraonline

Nice post. I learn something new and challenging on websites I stumbleupon on a daily basis. It’s always helpful to read content from other writers and practice something from their web sites.

byueuropaviagraonline

vavada czy to oszustwo [url=https://www.vavada2003.help]https://www.vavada2003.help[/url]

1win пополнение Optima через приложение [url=http://1win12049.ru]1win пополнение Optima через приложение[/url]

Нужно казино? ап х современные игры, простой вход, понятный интерфейс и стабильная работа платформы. Играйте с компьютера и мобильных устройств в любое время без лишних сложностей.

самые дешевые цветы москва Курьер живые розы Москва

заказать цветы с доставкой в москве недорого Свежие композиции курьер Москва

вскрытие замков Замена замков – профессиональная замена замков на новые, более надежные модели. Обеспечиваем безопасность вашего дома или офиса с гарантией качества.

магазин ремней ремни.рф оригинальные модели из натуральной кожи для мужчин и женщин. Классические и современные дизайны, высокое качество материалов, аккуратная фурнитура и удобный выбор для любого стиля.

dyson v15 купить спб [url=https://pylesos-dn-kupit-8.ru/]pylesos-dn-kupit-8.ru[/url] .

пылесос dyson купить в спб [url=https://pylesos-dn-kupit-10.ru/]пылесос dyson купить в спб[/url] .

Самые качественные блины на штангу широкий выбор весов и форматов. Надёжные материалы, удобная посадка на гриф, долговечное покрытие. Подходят для фитнеса, пауэрлифтинга и регулярных тренировок.

сколько лететь из дубая до краби пхукет пхи пхи краби

заказать цветы дешево москва Букет служба день в день

санкт петербург магазин дайсон [url=https://pylesos-dn-kupit-8.ru/]pylesos-dn-kupit-8.ru[/url] .

дайсон купить спб [url=https://pylesos-dn-kupit-10.ru/]дайсон купить спб[/url] .

цена за 1 розу в москве Цветы с доставкой сегодня

https://auto.qa/rent/car/

vavada godziny wsparcia [url=http://vavada2003.help]http://vavada2003.help[/url]

1win налоги на выигрыш Кыргызстан [url=http://1win12049.ru]http://1win12049.ru[/url]

https://auto.qa/sale/car/all/

пылесосы dyson [url=https://pylesos-dn-kupit-8.ru/]pylesos-dn-kupit-8.ru[/url] .

сервис дайсон в спб [url=https://pylesos-dn-kupit-10.ru/]сервис дайсон в спб[/url] .

бесплатный тик ток мод тг скачать тикток мод последняя версия андроид бесплатно

рунетки онлайн рунетки онлайн

https://diigo.com/011uafn When I first began researching gas fireplaces, I didn’t expect the market to be so varied. There are noticeable differences between brands in terms of materials, burner technology, and flame realism. Reading detailed product information and real usage feedback helped me understand what actually matters in the long run — things like maintenance access, fuel efficiency, and consistent performance. It’s definitely not something you want to choose only based on cost or visual design alone

mostbet.kg [url=www.mostbet2028.help]www.mostbet2028.help[/url]

A sports portal https://sbs-sport.com.az with breaking news, statistics, and expert commentary. Match schedules, transfers, interviews, and competition results are available in real time.

Live match https://sporx.com.az/ results, the latest sports news, transfers, and today’s TV schedule. Live updates, key events, and all sports information in one portal.

1win чат поддержки [url=https://www.1win12049.ru]1win чат поддержки[/url]

vavada kupon promocyjny [url=www.vavada2003.help]vavada kupon promocyjny[/url]

работа за границей с проживанием работа в корее для девушек

дайсон где купить в спб [url=https://pylesos-dn-kupit-8.ru/]pylesos-dn-kupit-8.ru[/url] .

1win balance kg вывод [url=http://1win12049.ru]http://1win12049.ru[/url]

пылесосы дайсон [url=https://pylesos-dn-kupit-10.ru/]пылесосы дайсон[/url] .

vavada aviator [url=vavada2003.help]vavada aviator[/url]

пылесос дайсон v15 купить в спб [url=https://pylesos-dn-kupit-8.ru/]pylesos-dn-kupit-8.ru[/url] .

vavada pravila turnira [url=https://vavada2010.help]https://vavada2010.help[/url]

дайсон спб официальный магазин [url=https://pylesos-dn-kupit-10.ru/]дайсон спб официальный магазин[/url] .

рунетки рунетки

Live streams golvar.com.az/ and live matches online, including the latest football schedule for today. Follow games in real time, find out dates, start times, and key events of football tournaments.

Нужна курсовая? курсовая работа на заказ Подготовка работ по заданию, методическим указаниям и теме преподавателя. Сроки, правки и сопровождение до сдачи включены.

скачать тик ток мод 3 версия новый тик ток мод

vavada live chat hrvatska [url=www.vavada2010.help]www.vavada2010.help[/url]

мостбет зеркало 2026 [url=http://mostbet2028.help]http://mostbet2028.help[/url]

Авиабилеты по низким ценам https://tutvot.com посуточная аренда квартир, вакансии без опыта работы и займы онлайн. Актуальные предложения, простой поиск и удобный выбор решений для путешествий, работы и финансов.

https://writeablog.net/larrybrown190/transform-your-living-space-with-a-modern-gas-fireplace Gas fireplaces have come a long way in terms of energy efficiency and safety features compared to earlier generations. During my research into different brands is that even within the same fuel type, heat distribution and control precision can vary a lot. Certain manufacturers focus on smart controls and flame customization, while others emphasize durability and simpler mechanical designs. Being aware of these distinctions really helps when selecting a fireplace that fits both the house layout and regular usage patterns during the heating season.

рунетки чат рунетки

vavada minimalna uplata eur [url=vavada2010.help]vavada2010.help[/url]

Зеркала для ванных комнат Зеркало с подсветкой – комфорт и удобство каждый день.

Зеркало гримерное Цена зеркала трюмо – у нас самые выгодные предложения!

most bet [url=https://mostbet2028.help/]most bet[/url]

лайф арена москва афиша концертов 2026 «Live Арена» — пространство для артистов разных жанров: от ярких шоу до уютных акустических концертов. Цена билетов зависит от события и категории мест — партер, балконы, лаунжи, ложи или премиум-боксы. Купить билет можно онлайн: выберите мероприятие, отметьте места на схеме зала, укажите контакты и оплатите заказ. Электронные билеты придут на почту сразу после оплаты.

мостбет обновление android [url=www.mostbet2028.help]www.mostbet2028.help[/url]

La fase de apuesta te da la oportunidad de configurar tu inversiГіn base, y en el momento como seleccionas en “Jugar”, el aviГіn despega en un recorrido con una trayectoria impredecible.

https://aviamasters.nom.es/

pinup bahis [url=http://pinup2008.help]http://pinup2008.help[/url]

pin-up transferencia BancoEstado [url=https://www.pinup2002.help]https://www.pinup2002.help[/url]

https://writefreely.ethibox.fr/larrybrown190/how-to-make-your-home-a-cozy-retreat-for-every-season

When researching space heaters, I noticed that Comfort Glow models are often mentioned in discussions about practical efficiency and safety. For smaller rooms or additional heat, those factors tend to be more important than max output.

Looking at various heater manufacturers helped me understand how airflow, thermostat control, and built-in protection systems affect everyday comfort. It’s not always about the highest heat level, but about consistent operation and reliable safety over time.

заклепка вытяжная 4 8х12 заклепки вытяжные усиленные

заклепка вытяжная отверстие заклепка вытяжная нержавеющая

https://prathamonline.com/

https://astra-hotel.ch/

pin-up canlı chat dəstək [url=https://pinup2008.help]https://pinup2008.help[/url]

пылесос дайсон купить в спб [url=https://pylesos-dn-kupit-8.ru/]пылесос дайсон купить в спб[/url] .

pin-up rəsmi giriş [url=www.pinup2008.help]pin-up rəsmi giriş[/url]

магазин дайсон в спб [url=https://pylesos-dn-kupit-10.ru/]магазин дайсон в спб[/url] .

pin-up canlı mərc [url=www.pinup2008.help]www.pinup2008.help[/url]

Зеркала под заказ Зеркала в металлической раме: прочные и стильные зеркала, которые станут акцентом в любом интерьере.

Месяц назад перешёл на кракен даркнет маркет после закрытия старой площадки

Актуальный адрес krab ссылка на маркетплейс обновляется при каждой блокировке

Зеркала под заказ Зеркала с подсветкой: создайте комфортное и функциональное освещение в ванной комнате или спальне.

pin-up retiro mínimo Chile [url=https://pinup2002.help]https://pinup2002.help[/url]

Зеркало трюмо купить в Москве Поворотное зеркало в полный рост – оцените свой наряд целиком.

Романы для любителей глубокой прозы Обзоры, рецензии и авторские тексты о книгах

https://neymar-az.org/user/harinngjkp

https://www.multichain.com/qa/1xbet-bonuscode

https://campuspress-test.yale.edu/cnspy/wp-comments-post.php

пошив римских штор Пошив римских штор требует высокой точности и мастерства, так как каждая деталь имеет значение. Правильно подобранная ткань и фурнитура, а также качественный пошив гарантируют долговечность и эстетичный внешний вид.

мешки 360 литров Мусорные мешки 240л представляют собой оптимальное решение для бытового использования, обеспечивая удобство и гигиеничность при сборе и утилизации мусора.

Hmm is anyone else encountering problems with the pictures on this blog loading? I’m trying to find out if its a problem on my end or if it’s the blog. Any responses would be greatly appreciated.

казино рио бет

кайтинг в тайланде кайт на пхукете

pin-up Chile sitio [url=pinup2002.help]pinup2002.help[/url]

Whats up are using WordPress for your blog platform? I’m new to the blog world but I’m trying to get started and set up my own. Do you require any html coding knowledge to make your own blog? Any help would be greatly appreciated!

вход RioBet Casino

http://vaiu.ru/images/pages/index.php?1xbet_promokod_na_besplatnuu_stavku.html

descargar pin up app [url=pinup2002.help]pinup2002.help[/url]

Сезон для «Трактора» получается плотным и эмоциональным: борьба в каждом матче и аншлаги на арене. В статье рассказывается о стиле команды, домашних играх, выездах и о том, почему билеты разбирают весь чемпионат. Подробнее — по ссылке https://telegra.ph/Hokkejnyj-klub-Traktor-sezon-napryazhennoj-borby-i-yarkih-matchej-01-21 .

1xbet giri? [url=https://1xbet-yeni-giris-2.com/]1xbet giri?[/url] .

mostbet кэшбэк [url=https://mostbet94620.help]https://mostbet94620.help[/url]

vavada depozyt blik [url=http://vavada2004.help/]http://vavada2004.help/[/url]

В Театре Наций каждый спектакль звучит по-разному, но всегда честно. В тексте — о постановках, которые заставляют задуматься и почувствовать, и о редком ощущении живого контакта со сценой. Читать далее https://kulturologia.ru/blogs/071225/66534/ .

Hi everyone, it’s my first go to see at this web page, and article is in fact fruitful in support of me, keep up posting these posts.

https://share.google/4dNTE6MSafbUf3j5y

1xbet spor bahislerinin adresi [url=https://1xbet-yeni-giris-2.com/]1xbet spor bahislerinin adresi[/url] .

мостбет кэшбэк казино [url=https://www.mostbet94620.help]https://www.mostbet94620.help[/url]

Интернет-магазин химических реактивов https://magazinreactivov.ru для учебных, научных и производственных задач. В каталоге — реактивы разных классов чистоты, расходные материалы и сопутствующие товары. Помогаем подобрать позиции под вашу задачу, предоставляем документы. Удобный заказ онлайн, актуальные цены и наличие, доставка по России.

1x lite [url=https://1xbet-yeni-giris-2.com/]1xbet-yeni-giris-2.com[/url] .

Our top selection: https://beh.sk/

мостбет скачать apk Кыргызстан [url=http://mostbet94620.help]http://mostbet94620.help[/url]

Для миття cleaninglviv.top вікон

мостбет рабочий сайт Кыргызстан [url=http://mostbet94620.help]http://mostbet94620.help[/url]

vavada szybka rejestracja [url=https://www.vavada2004.help]https://www.vavada2004.help[/url]

ДВС и КПП https://vavtomotor.ru автозапчасти для автомобилей с гарантией и проверенным состоянием. В наличии двигатели и коробки передач для популярных марок, подбор по VIN, быстрая доставка и выгодные цены.

1x bet giri? [url=https://1xbet-yeni-giris-2.com/]1xbet-yeni-giris-2.com[/url] .

1win бонусы казино [url=https://1win21567.help/]https://1win21567.help/[/url]

Играешь в казино? болливуд казино казино на деньги играть красочный игровой автомат с бонусами, фриспинами и высокими выигрышами. Доступно бесплатно или на реальные деньги, поддержка мобильных устройств.

Купить билет в «Лайв Арену» в Москве От танцевальных марафонов до камерных, но мощных лайвов — Live Арена держит высокую планку. В статье рассказывают, какие концерты нельзя пропустить и чем они цепляют

Ищешь казино? clubnika club casino играйте онлайн в игровые автоматы и live-казино. Бонусные предложения, демо-режим, мобильная версия и круглосуточный доступ к азартным играм без установки.

Лушчее онлайн казино pinco casino online слоты, live-казино и бонусные функции. Доступ с любых устройств, понятный интерфейс и возможность выбрать бесплатный или реальный режим игры.

vavada wpłata tpay [url=vavada2004.help]vavada wpłata tpay[/url]

1win Бишкек кирүү [url=http://1win62940.help]http://1win62940.help[/url]

https://www.loveyourrebellion.org/pag/promotion_codes___discounts.html

Лучшее онлайн казино pinco казино онлайн играть слоты, live-казино и бонусные функции. Доступ с любых устройств, понятный интерфейс и возможность выбрать бесплатный или реальный режим игры.

1xbetgiri? [url=https://1xbet-yeni-giris-2.com/]1xbet-yeni-giris-2.com[/url] .

Awesome things here. I’m very happy to see your post. Thank you so much and I am having a look forward to contact you. Will you kindly drop me a e-mail?

посоветуйте где заказать дипломную работу

Играть онлайн пинко casino играть игровые автоматы, live-казино и бонусы для новых игроков. Удобный интерфейс, доступ с телефона и ПК, возможность играть бесплатно или на реальные ставки.

vavada statystyki meczowe [url=http://vavada2004.help]http://vavada2004.help[/url]

Thanks , I have recently been searching for information approximately this topic for a long time and yours is the best I’ve discovered till now. But, what in regards to the conclusion? Are you sure in regards to the source?

сайт для дипломной работы

Играть в казино 1 вин казино лоты, live-столы и бонусные функции. Подходит для новичков и опытных игроков, доступно бесплатно и на реальные деньги 24/7.

Казино онлайн лучшие лицензионные онлайн казино играйте онлайн в яркие слоты и live-казино. Динамичный игровой процесс, бонусные раунды и возможность начать игру за пару кликов с телефона или компьютера.

Лучшее онлайн казино казино где можно использовать мир играйте в слоты и live-казино с телефона или ПК. Адаптивный интерфейс, быстрый запуск игр и доступ к развлечениям в любое время.

Залетай в казино шуга раш быстрый доступ к слотам, live-играм и настольным развлечениям. Удобная навигация, запуск без установки и поддержка мобильных устройств.

Топовое онлайн казино new retro casino бездепозитный бонус за регистрацию играть онлайн с телефона или ПК. Слоты и live-игры, адаптивный интерфейс и стабильный запуск без скачивания приложений.

Купить билеты в Театр Вахтангова онлайн Театр Вахтангова — место, где сцена превращается в живое пространство диалога. Здесь форма и содержание идут рядом, усиливая друг друга и создавая цельное впечатление.

Details on the page: https://jigsaw.w3.org/css-validator/validator?uri=http://coberm.net%2F&profile=css3&usermedium=all&vextwarning=true

1вин регистрация [url=1win62940.help]1win62940.help[/url]

https://trout-league.ru/images/pages/?promokod_240.html

aviator игра 1win [url=http://1win62940.help/]http://1win62940.help/[/url]

1win валюта аккаунта [url=https://1win21567.help]https://1win21567.help[/url]

1win ошибка 404 [url=https://www.1win62940.help]https://www.1win62940.help[/url]

bahis sitesi 1xbet [url=https://1xbet-yeni-giris-2.com/]bahis sitesi 1xbet[/url] .

Михайловский театр афиша Балет в Петербурге — это не просто спектакль, а часть городской души. Здесь классика живёт рядом с экспериментом, а сцена Михайловского театра превращает танец в разговор о чувствах, времени и красоте, к которым хочется возвращаться снова и снова.

дизайн ванной коттеджа дизайн проект коттеджа

дизайн кухни в коттедже дизайн интерьеров домов коттеджей

1win ошибка входа [url=www.1win21567.help]www.1win21567.help[/url]

https://emigranto.ru/blog/mostbet_promokod_na_segodnya.html

vavada casino registracija [url=https://www.vavada2009.help]https://www.vavada2009.help[/url]

Зеркала под заказ Сдвижные зеркала: современное решение для экономии пространства.

1win статистика [url=http://1win21567.help/]1win статистика[/url]

1win crash игра [url=www.1win74125.help]www.1win74125.help[/url]

производство картонной упаковки москва Гофрокороба под заказ – это искусство превращения функциональной упаковки в произведение инженерной мысли. Индивидуальный дизайн, учитывающий особенности товара и требования к транспортировке, позволяет создать оптимальную упаковку, обеспечивающую максимальную защиту и удобство использования.

Театр Одеон купить билеты Если хочется настоящего театра — без суеты и шаблонов, сюда стоит прийти. Каждая постановка создаётся для диалога и живого отклика зала.

онлайн обучение с выдачей диплома бьюти профессии Получение диплома бьюти-специалиста онлайн – это инвестиция в ваше будущее, открывающая двери в салоны красоты, спа-центры, частные практики и возможность создания собственного успешного бизнеса. Теоретические знания, практические навыки, экспертная поддержка и возможность получения обратной связи – все это делает онлайн-обучение эффективным и результативным.

спа Стерлитамак Массаж Стерлитамак – это врата в мир расслабления и восстановления, где умелые руки мастера преображают уставшее тело в источник энергии. В современном ритме жизни, когда стресс и напряжение становятся неизбежными спутниками, профессиональный массаж становится не просто приятной процедурой, а необходимостью для поддержания физического и эмоционального здоровья. От классических техник, снимающих мышечное напряжение и улучшающих кровообращение, до специализированных видов массажа, направленных на решение конкретных проблем, в Стерлитамаке каждый найдет свой идеальный путь к гармонии и благополучию. Позвольте себе ощутить прикосновение заботы и почувствуйте, как усталость покидает ваше тело, а разум наполняется спокойствием и ясностью.

производство картонной упаковки москва Упаковка гофрокороб – это фундамент безопасной транспортировки и презентабельного представления вашей продукции. От прочности материала до эргономичности конструкции, каждый аспект гофрокороба играет ключевую роль в сохранении целостности товара и создании положительного впечатления у потребителя. Выбор правильной упаковки – это стратегическое решение, определяющее успех вашего бизнеса.

Hi there! This is my first comment here so I just wanted to give a quick shout out and say I genuinely enjoy reading through your articles. Can you suggest any other blogs/websites/forums that go over the same subjects? Thank you!

https://share.google/zT4LNSKwxGVSAXCDR

At this time it seems like Drupal is the preferred blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

https://share.google/pjDqDZ3YgbiOV8JUu

https://dukesavenue.com/wp-admin/articles/?code-promo-linebet_bonus-sportifs-et-casino.html

Зеркало поворотное косметическое Зеркало трюмо – классика, которая никогда не устареет.

vavada minimalna uplata paysafecard [url=https://vavada2009.help/]https://vavada2009.help/[/url]

https://medium.com/@seoblogspro/a-guide-to-top-betting-sites-and-exclusive-welcome-bonus-promotions-d4a4ce511f04?postPublishedType=initial

mostbet descarcare app android [url=mostbet2010.help]mostbet2010.help[/url]

free bet promo code 1xbet azerbaijan

Купить билет в Театр имени Пушкина онлайн Здесь классика говорит современным языком. Через точную интонацию и игру актёров спектакли находят отклик у зрителя сегодня.

1win сайт 1вин 1вин, с его славянским шармом, манит как запретный плод в саду соблазнов. Локализованный для русскоязычных искателей приключений, он предлагает лабиринт игр, где каждый поворот таит сокровища. От живых дилеров в казино до киберспортивных арен – 1вин обеспечивает безопасность, словно неприступная крепость, с многоуровневым шифрованием. Здесь бонусы расцветают пышно, а поддержка шепчет советы на родном языке, превращая обыденность в грандиозный фестиваль выигрышей.

аренда Mercedes V class с водителем на два дня аренда Mercedes V class с водителем на два дня «аренда Mercedes V class с водителем на два дня» предполагает более длительное мероприятие, возможно, за городом или с ночевкой, где необходим надежный и комфортабельный транспорт на протяжении всего периода.

изготовление индивидуальной упаковки Гофрокороба под заказ – это искусство превращения функциональной упаковки в произведение инженерной мысли. Индивидуальный дизайн, учитывающий особенности товара и требования к транспортировке, позволяет создать оптимальную упаковку, обеспечивающую максимальную защиту и удобство использования.

журнал про авто [url=https://avto-zhurnal-4.ru/]журнал про авто[/url] .

vavada ograničenja uplate [url=http://vavada2009.help]http://vavada2009.help[/url]

1xbet bonus code nepal

vavada kasino slotovi [url=www.vavada2009.help]www.vavada2009.help[/url]

дизайны комнат в квартире двухкомнатная квартира 53 кв м дизайн

дизайн гостиной в квартире дизайн двухкомнатной квартиры 56 кв

1вин 1win зеркало Когда основной доступ заблокирован, 1win зеркало становится спасением. Актуальное 1win зеркало обновляется ежедневно, обеспечивая бесперебойный вход. Используйте 1win зеркало, чтобы не пропустить матчи или бонусы – это надежный способ обойти ограничения.

1win пополнение с карты Кыргызстан [url=https://1win74125.help]https://1win74125.help[/url]

трансфер мерседес межгород аренда Mercedes V class с водителем на 2 месяца Еще более продолжительный срок «аренда Mercedes V class с водителем на 2 месяца» характерен для сезонных рабочих контрактов, длительных ремонтных работ вдали от дома или для гостей столицы, проводящих в России целый сезон.

журнал про автомобили [url=https://avto-zhurnal-4.ru/]журнал про автомобили[/url] .

promo code for 1xbet philippines

https://illustrators.ru/users/theoryiron/about

1win лаки джет [url=1win74125.help]1win лаки джет[/url]

журналы для автолюбителей [url=https://avto-zhurnal-4.ru/]avto-zhurnal-4.ru[/url] .

mostbet cote tenis [url=http://mostbet2010.help/]http://mostbet2010.help/[/url]

Купить билеты в Большой драматический театр Здесь удобно выбрать спектакль на вечер и сразу понять, что подойдёт именно вам. Актуальная афиша, понятное расписание и возможность не тратить время на поиски — просто выбрать и пойти в театр.

http://julia4tied.de/member.php?action=profile&uid=240023

1win скачать на ios [url=1win74125.help]1win скачать на ios[/url]

1win contacto [url=http://1win38941.help/]1win contacto[/url]

Soft Rock Soft Hard Rock Soft hard rock – это апогей его творческого поиска, где контрасты сливаются воедино, создавая неповторимую музыкальную палитру. Этот жанр – словно яркий закат, в котором мягкие пастельные тона переходят в насыщенные, огненные оттенки. Soft hard rock – это музыка, рождающаяся на грани двух миров, воплощающая в себе всю гамму человеческих эмоций.

арматура Купить Арматуру в МСК В условиях жесткой конкуренции московского рынка особенно важно найти оптимальное предложение. Купить арматуру в МСК – это значит воспользоваться широким выбором, выгодными ценами и оперативной доставкой от ведущих столичных поставщиков.

центр сертификации официальный сайт Центр сертификации официальный сайт Центр сертификации официальный сайт публикует актуальную информацию о своей деятельности.

http://socialhungari.ru/2024/06/02/melbet-promokod-na-stavku-2026-max888-bonus-15000%e2%82%bd/?preview=true

Пространство для болельщиков, которым важно попасть на игру без лишних сложностей. Всё нужное — в одном месте https://postheaven.net/tickethockey-com/bilety-na-hokkey .

Мы ответственно делаем качественно тумбы мебель на заказ москва прямо с производства. Конструкторская схема без задержек. Проверка после монтажа без мусора. Запросите смету – подберем материалы.

журнал про автомобили [url=https://avto-zhurnal-4.ru/]журнал про автомобили[/url] .

1xbet promo code hong kong 2026

mostbet cum pun un pariu [url=mostbet2010.help]mostbet cum pun un pariu[/url]

Soft Hard Rock Soft Но Aleks Qt не ограничивает себя рамками одного направления. В его музыке проскальзывают нежные нотки soft, придавая его композициям лиричность и глубину. Soft – это момент тишины перед бурей, возможность остановиться и заглянуть в глубину своей души.

https://lt.livesexchat18.com/

mostbet селфи барои тасдиқ [url=http://mostbet80573.help]http://mostbet80573.help[/url]

mostbet probleme depunere [url=https://mostbet2010.help]mostbet probleme depunere[/url]

Сертификация продукции https://www.sostav.ru/blogs/286052 подтверждение того, что продукция соответствует нормам безопасности. Сертификация обязательна для некоторых групп товаров. Помимо обязательной, есть и добровольная сертификация соответствия продукции действующим стандартам. Её проводят по запросу производителя, импортёра или продавца.

сертификат компании Сертификат цена Сертификат цена может складываться из затрат на испытания, экспертизу и оформление документа.

арматура а500с Арматура 12 купить в москве Арматура 12 купить в москве очень просто, главное знать к кому обращаться.

1win fútbol Perú [url=https://www.1win38941.help]https://www.1win38941.help[/url]

Сертификация услуг https://pandia.org/user/categ/6225-Moi_statmzi это процедура подтверждения стабильного уровня качества и безопасности предоставляемых услуг. Схемы сертификации услуг. В российской практике сертификация услуг регламентирована национальными стандартами, в частности, ГОСТ Р 54659-2011.

https://freesexcams.pw/

car журнал [url=https://avto-zhurnal-4.ru/]car журнал[/url] .

Soft Hard Rock А с другой стороны – мощный напор hard rock, взрывающийся шквалом гитарных риффов и громогласных барабанов. Hard Rock – это квинтэссенция энергии и драйва, гимн силе духа и непоколебимости. Это музыка, заряжающая адреналином, дающая силы для борьбы и преодоления любых препятствий.

cómo hacer retiro en 1win [url=https://www.1win38941.help]https://www.1win38941.help[/url]

viralshift.click – Navigation felt smooth, found everything quickly without any confusing steps.

leadcircuit.click – Navigation felt smooth, found everything quickly without any confusing steps.

1xbet promo code today somalia

Hard Rock Soft Hard Rock Soft hard rock – это апогей его творческого поиска, где контрасты сливаются воедино, создавая неповторимую музыкальную палитру. Этот жанр – словно яркий закат, в котором мягкие пастельные тона переходят в насыщенные, огненные оттенки. Soft hard rock – это музыка, рождающаяся на грани двух миров, воплощающая в себе всю гамму человеческих эмоций.

seobeacon.click – Navigation felt smooth, found everything quickly without any confusing steps.

1win depósito no acreditado [url=https://www.1win38941.help]1win depósito no acreditado[/url]

https://erochats.net/

1xbet promo code nigeria 2026

netamplify.click – Navigation felt smooth, found everything quickly without any confusing steps.

сертификация онлайн Сертификация товара цена Сертификация товара цена зависит от вида продукции, схемы сертификации и аккредитации органа по сертификации.

арматура цена Арматура 12 А500С Марка стали имеет решающее значение. «Арматура 12 А500С» – это оптимальный выбор для большинства строительных задач, обеспечивающий высокую прочность и надежность конструкции.

Wlasnie odkrylem swietne kasyno: Spinania Casino z darmowymi spinami za sama rejestracje.

Aleks Qt Рок В основе его музыкального мировоззрения лежит рок, бунтарский дух свободы и протеста. Это не просто жанр, это философия, отражение жизненной позиции, его способ говорить с миром на языке гитарных рифов и пульсирующих барабанов.

https://rf.livesexchat18.com/all-models

Лучшие и безопасные противопожарные резервуары купить эффективное решение для систем пожарной безопасности. Проектирование, производство и монтаж резервуаров для хранения воды в соответствии с требованиями нормативов.

1вин plinko [url=https://1win30489.help]https://1win30489.help[/url]

promo code for 1xbet kenya

mostbet lucky jet Тоҷикистон [url=www.mostbet80573.help]www.mostbet80573.help[/url]

Бесплатные курсы ЕГЭ https://courses-ege.ru

https://maturecams.pw/

https://pornochat.moscow/

Противопожарный резервуар для воды подземный https://underground-reservoirs.ru

https://rt.virt888.com/

мостбет воридкунии маблағ [url=mostbet80573.help]мостбет воридкунии маблағ[/url]

pin-up email dəyişmək [url=https://www.pinup2006.help]pin-up email dəyişmək[/url]

мостбет бо корт [url=https://mostbet80573.help/]мостбет бо корт[/url]

1win бонус активировать при регистрации [url=http://1win30489.help]http://1win30489.help[/url]